Welding is one of the most essential fabrication processes in modern manufacturing, construction, and engineering industries. From automobiles and ships to skyscrapers and pipelines, welding creates the permanent joints that hold structures together. Traditionally, welding has been carried out by skilled human welders. However, as industries demand higher efficiency, consistency, safety, and cost reduction, welding robots have emerged as a revolutionary technology.

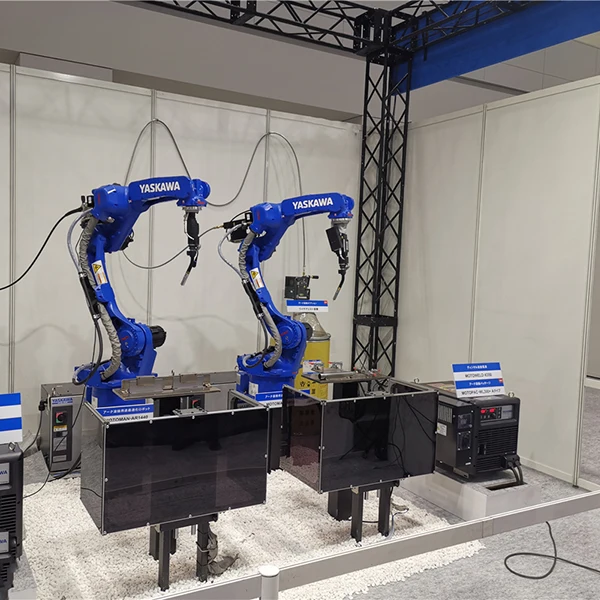

A welding robot is a programmable mechanical arm or automated system designed to perform welding tasks with precision and repeatability. These machines are equipped with advanced sensors, controllers, and welding tools, enabling them to perform a wide range of welding operations that would otherwise require significant human effort.

In today’s manufacturing world, welding robots have become one of the most important tools for achieving precision, productivity, and safety. Welding is a process that permanently joins metals, and it has been traditionally carried out by skilled human welders. However, with the rise of industrial automation, robotic welding systems have gained massive popularity.

A welding robot is a programmable machine designed to carry out welding tasks such as MIG welding, TIG welding, arc welding, and spot welding. These robots are widely used in industries like automotive, aerospace, construction, shipbuilding, and electronics. By using robotic welding systems, companies can improve efficiency, reduce costs, and achieve consistent welding quality.

This article explores the evolution, types, working principles, applications, advantages, challenges, and future of welding robots, while highlighting essential welding robot keywords for technical and industrial understanding.

In today’s manufacturing world, welding robots have become one of the most important tools for achieving precision, productivity, and safety. Welding is a process that permanently joins metals, and it has been traditionally carried out by skilled human welders. However, with the rise of industrial automation, robotic welding systems have gained massive popularity.

A welding robot is a programmable machine designed to carry out welding tasks such as MIG welding, TIG welding, arc welding, and spot welding. These robots are widely used in industries like automotive, aerospace, construction, shipbuilding, and electronics. By using robotic welding systems, companies can improve efficiency, reduce costs, and achieve consistent welding quality.

This article explores the evolution, types, working principles, applications, advantages, challenges, and future of welding robots, while highlighting essential welding robot keywords for technical and industrial understanding.

The concept of robotic welding dates back to the 1960s.

1961: Unimation created the first industrial robot for material handling.

1969: Kawasaki introduced the first dedicated welding robot for automotive spot welding.

1970s–1980s: The automobile industry rapidly adopted welding automation.

1990s: Improved sensors, CNC controls, and programming expanded robotic welding applications.

2000s–Present: AI-powered welding robots with real-time monitoring, adaptive control, and vision systems dominate modern factories.

Today, welding robots are essential in Industry 4.0 smart manufacturing environments.

A robotic welding system consists of several integrated components:

Robotic Arm: Multi-axis arm that positions the welding torch with precision.

Controller: Acts as the robot’s brain, storing programs and controlling movement.

End Effector (Welding Torch): The tool that performs MIG, TIG, or arc welding.

Power Supply: Provides stable electrical energy for the welding process.

Sensors & Vision Systems: Detect joint positions, gaps, and welding defects.

Safety Features: Includes barriers, alarms, and emergency stop mechanisms.

Depending on the welding process, robots are classified into:

Arc Welding Robots

Use MIG welding and TIG welding processes.

Common in automotive, aerospace, and heavy industries.

Spot Welding Robots

Designed for joining sheet metals in car body assembly lines.

Can perform thousands of welds in minutes.

Laser Welding Robots

Use high-intensity laser beams for clean, precise welds.

Essential in electronics, aerospace, and medical device industries.

Plasma Welding Robots

Provide deep penetration welds with high accuracy.

Ideal for critical aerospace applications.

Hybrid Welding Robots

Combine multiple processes, such as arc + laser, for advanced welding tasks.

The welding robot process follows these steps:

Programming the Robot: Using a teach pendant or CAD/CAM software.

Positioning: The robotic arm moves the welding torch to the exact joint location.

Arc Initiation: Power supply generates an arc between the electrode and the metal.

Welding Process: Sensors monitor parameters such as current, voltage, and temperature.

Quality Check: Vision systems detect any defects in the weld.

Welding robots are widely used across industries:

Automotive Industry: Spot welding and arc welding in vehicle frames and chassis.

Shipbuilding: Large-scale arc welding for ship hulls.

Aerospace: TIG welding robots for lightweight alloys and precision components.

Oil & Gas Pipelines: Automated welding for long pipelines in harsh environments.

Construction: Steel welding for skyscrapers, bridges, and infrastructure.

Electronics & Medical Devices: Laser welding robots for micro-welding tasks.

The adoption of robotic welding systems offers numerous benefits:

Precision & Consistency – Produces uniform welds with minimal errors.

Higher Productivity – Welding robots work continuously without breaks.

Safety – Reduces human exposure to toxic fumes, sparks, and heat.

Cost Savings – Reduces labor costs and rework expenses.

Flexibility – Robots can be reprogrammed for different welding applications.

Data Collection – Robots provide welding analytics for quality control.

Despite their advantages, welding robots have some limitations:

High Initial Investment – Expensive installation and setup.

Complex Programming – Skilled technicians required.

Not Ideal for Small Batches – Best suited for mass production.

Maintenance Needs – Frequent calibration and servicing.

Job Displacement Concerns – Fewer roles for manual welders.

Safety is critical when using arc welding robots or laser welding robots:

Protective enclosures to prevent accidental exposure.

Fume extraction systems for hazardous gases.

Emergency stop controls for quick shutdowns.

Training programs for human operators and supervisors.

The future of robotic welding technology is shaped by AI, IoT, and smart automation:

AI-Driven Welding Robots: Self-adjusting parameters for optimized welds.

Collaborative Welding Robots (Cobots): Work alongside humans safely.

Cloud-Based Monitoring: Remote tracking of welding quality and efficiency.

Advanced Vision Systems: Real-time detection of defects and misalignment.

3D Printing + Welding Robots: Combining additive manufacturing with welding.

Welding robot

Robotic welding

Arc welding robot

MIG welding robot

TIG welding robot

Spot welding robot

Laser welding robot

Industrial welding automation

Advantages of welding robots

Welding robot applications

Robotic welding system

Welding automation technology

Welding robots have revolutionized modern manufacturing by providing speed, precision, and safety. From arc welding robots in car factories to laser welding robots in aerospace, these machines ensure consistent and reliable welds.